Mike Dawson – republished with permission

With the continuing plague of mechanical fuel pump failures that I have encountered recently, I made the decision to do some converting. Why Corvair pumps are such a problem to manufacture correctly is an unanswered question. Do all aftermarket mechanical fuel pumps fail on a regular basis? I doubt it, and although a failed pump is neither expensive nor difficult to change it should not be a continuing issue with an otherwise delightful car. Leaks are the latest issue, and there is now a red warning card inside the Airtex box advising about tightening the screws during installation. However, more than one tightening is usually necessary and none of us wants to see a fire in the rear view mirror.

I recently installed an electric pump on my ’61 Lakewood wagon with the intention of determining the best location, type of pump and engine compartment fuel line configuration. I first installed an Airtex E8012S pump (5.5-9 psi) on the bottom/back of the trunk, just in front of the cross-member. That location makes it shielded from road debris, deep snow and floor jacks. I used 5/16” fuel hose for both inlet and outlet since that makes the pump easy to remove and replace if necessary (in my case I wanted to test more than one pump). Mounted with some miscellaneous rubber bushings it is very quiet and with the engine running it is not heard at all.

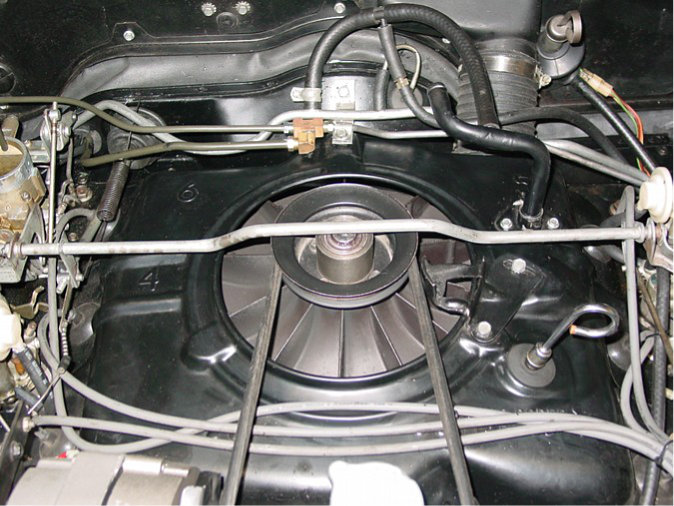

The engine compartment fuel line configuration presented several possibilities. I was routing for a 140 engine but all the others would be similar. I used the Clark’s fuel pump plug to fill the hole where the original pump was located and I fabricated a new inlet line from the rubber connection by the starter through the shroud and with a 90 degree turn to the center of the engine where I could mount the necessary T fitting (picture nearby). That also necessitated bending and double flaring one new 1⁄4” fuel line to the left side and using one of Clark’s pre-bent right side lines that just happened to fit. Overall the installation looks good and contains all double flare steel lines in the engine compartment.

Wiring is simple, a good ground and a power wire to the side of the fuse box; hot only with the key on. The current draw on the pump I installed is 0.9 amps, low enough that you could add that to your radio fuse. An inertia switch to shut off the pump in case of a crash is next.

I checked the fuel pressure delivered at a carburetor inlet and found that the E8012S pump provided 8 PSI. After driving the car for a week I replaced that pump with the E8016S pump which is a lower pressure unit (2.5-4 PSI). The pressure delivered at a carburetor was 4 PSI which is just under the original specification (4.5 PSI) for a Corvair pump from the factory. More test driving included a long hill at 70 with all four carburetors open: I encountered no fuel starvation.

Other Options:

Clark’s also offer a center block for the original pump that lets the fuel flow straight through; this eliminates fabricating lines and looks close to stock. I installed one of these on my late model sedan and it is an easier installation with no line routing; just disassemble and re-assemble the old mechanical pump using the original fittings.

I also looked at an option of using a series of fittings to eliminate the stock pump at its original location but discarded that idea; picture nearby.

Upsides to an electric pump:

- I have never seen one leak.

- Pump failure is very rare and vapor lock does not occur since the pump is near the tank and it is pushing fuel through all the hot spots instead of trying to create a vacuum as the original does.

- Peace of mind; you should not have to check your fuel pump at every stop while on a trip. Downsides to an electric pump.

- The electric pump has a small pre-filter, so you would need a clean tank and even then you should check the filter on a regular basis.

- Use of rubber fuel line at the pump would require yearly inspection for signs of deterioration (but it is only a 10 minute replacement job).

- If a failure did occur on the road, replacing the pump or pre-filter would require jacking up the vehicle.

- Costs could add up depending on what configuration you use, i.e. pump ($30), Clark’s plug ($10), Clark’s inertia switch ($83) and flow through fuel pump block ($46).

Those before me have used other pumps, locations and configurations; this is just my experience that I hope might be useful as a guide if you consider an electric pump. Be creative and share if you come up with a good idea.

*** Editors Note: Fast forward to 2023 – updated prices from Clark’s

Fuel Pump Plug C5406 $20.95

Fuel Pump By-Pass Plate C12879 $69.75

Electric Fuel Pump C5606 $76.95

We are extremely grateful to Corvair expert Mike Dawson (HACOA) for allowing CMoA to reprint and publish his technical writings.